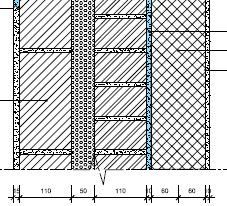

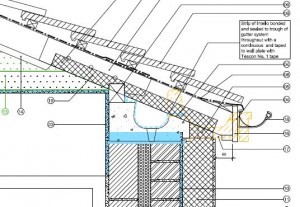

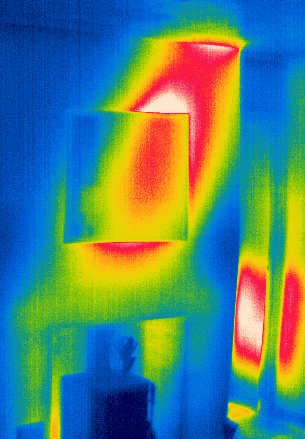

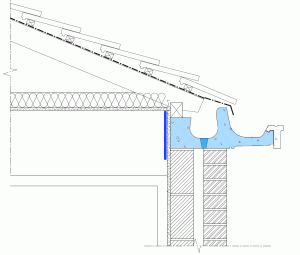

The rafters to the existing pitched roof have been extended now that the concrete gutters have been removed. This will allow the roof to extend sufficiently in front of the external wall insulation. The Intello air barrier membrane beneath the rafters is Tescon taped to the existing timber wall plate to reduce the air leakage out of the cavity head (see drawing in previous post).

We are also insulating between the rafters to provide insulation continuity between the external wall insulation and the loft insulation. The rigid insulation panels are squeezed tightly between the timbers and extend approx 0.5m above the (future) loft insulation. This means that they should also serve to provide a ventilation channel into the loft. This ventilation is necessary to remove any condensation from the cold loft space, and is often provided via proprietary ventilation channels.

New, matching roof tiles have been sourced. These will soon be fitted along with the new fascia and gutters – to be continued.