Yes, the rain came this week. 79mm fell here in 24 hours (Monday morning being the worst) – just perfect, absolutely perfect conditions to do anything other than dig the foundings for the new foundations! So, it has been slippy and sticky on site, which has meant slow progress. So not a huge amount to write about this week.

Not to despair, the guys have progressed as well as can be expected and have got the foundings prepared and ready for the first inspection by Building Control tomorrow (Friday). The concrete delivery is booked for the afternoon, immediately after the inspection sign off. So, all being well the foundations for the rear wall will be cast tomorrow. This is good as we’re expecting a dryish weekend before poor weather resumes next week.

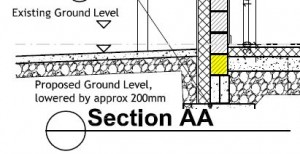

In an attempt to minimise the amount of concrete in our extra deep (1.2m) foundations (see earlier posts related to Wessex Water requirements), the design adopted uses 750 dia concrete pipes as opposed to a massive trench fill to this depth. The top photo of this entry shows 2 of the 4 foundings for these pipes. On top of these pipes will sit large lintels which we will build the walls off. Our contractor has sourced some off-cuts of 750dia ventilation ducts (photo below) which will be perfect for casting the foundations.

In the meantime, the underpinning has continued this week and the rear wall is now fully underpinned. This has gone well, but there’s more to be done as we work our way up the slope of the house. The photo below shows the, recently poured, underpinning section with the formwork and bracing (granted not the most interesting picture, but I am a bit short of visuals this week!).